Leather. It’s a material that speaks of quality, durability, and timeless style. Whether you’re a designer crafting the next iconic handbag, a product developer sourcing materials for rugged footwear, or a brand building a reputation on excellence, understanding the nuances of leather is paramount.

One of the most talked-about aspects? Waterproofing.

Get it right, and you enhance the longevity and performance of your leather goods. Get it wrong, and you risk damaging premium hides, misleading customers, or compromising your product’s integrity.

This comprehensive guide dives deep into the world of leather waterproofing. We’ll debunk common myths, explore the best methods for different leather types, and equip you with the knowledge to make informed decisions – ensuring your leather products not only look exceptional but also stand up to the elements.

Let’s get started.

Chapter 1: Waterproof vs. Water-Resistant Leather – Decoding the Lingo

First things first: let’s clear up some common confusion. The terms “waterproof” and “water-resistant” are often used interchangeably, but they mean very different things, especially when it comes to leather.

Water-resistant leather can withstand a certain degree of water exposure. Light rain or a minor spill might bead up and roll off, but under sustained exposure or pressure, water will eventually penetrate. Most leather, especially if untreated, falls into this category due to its naturally porous structure. Think of it as a temporary shield.

In contrast, waterproof leather implies the material is impervious to water. This means water will not penetrate it, even when submerged for a period. Achieving true, 100% waterproofness in leather is rare. It often involves significant treatments or integrated technologies like membranes. Materials like rubber or plastic are inherently waterproof; leather, being organic, is not.

Why is this distinction critical? For product development and consumer expectations, clarity is key. Promising “waterproof” when a product is merely “water-resistant” can lead to disappointment and damage. Understanding this difference is the foundation of effective leather care and quality product design.

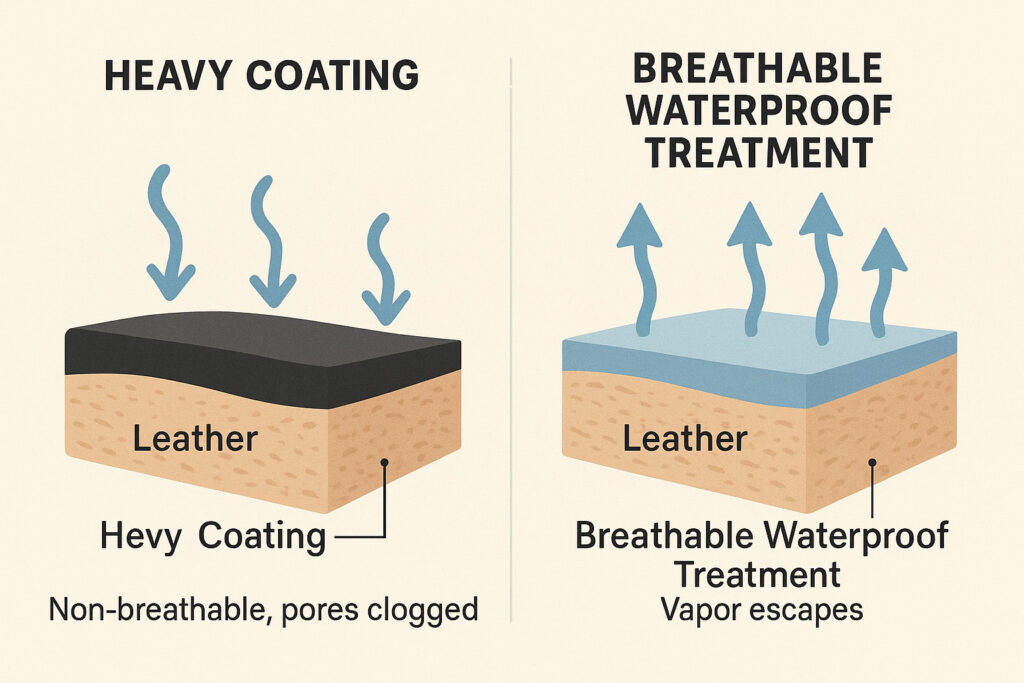

The Breathability Trade-Off: A crucial point to remember is that often, the more waterproof a material is, the less breathable it becomes. Heavy coatings that seal leather pores to block water can also trap moisture vapor (like sweat). This can lead to discomfort in apparel or footwear. We’ll explore this balance in more detail later.

Chapter 2: Waterproofing Leather: The 5 Myths You Need to Stop Believing

The internet is awash with advice on leather care, but not all of it is accurate. When it comes to waterproofing, misinformation can be particularly damaging. Let’s bust some of the most persistent myths.

Myth #1: All Leather is Naturally Waterproof (or Can Be Made 100% Waterproof). The truth is, this is a fundamental misunderstanding. As we’ve established, leather is porous. While some high-quality leathers like full-grain possess a degree of natural water resistance due to their dense fiber structure , no untreated leather is truly waterproof. Achieving something close to 100% waterproofing typically involves heavy coatings or specialized tannery processes. These can sometimes alter the leather’s natural feel and breathability. The practical goal for most leather goods is achieving effective water resistance, not absolute impermeability.

Myth #2: Waterproofing Sprays Are a Universal Fix for All Leather Types. This is a dangerous and widespread myth. While sprays offer undeniable convenience , applying them to full-grain smooth leather can be detrimental in the long run. Many sprays, particularly those containing silicone, can form a surface barrier. This barrier repels water, but it can also prevent essential nourishing ingredients from leather creams and conditioners from penetrating the hide. Over time, this can lead to the leather drying out from within and potentially cracking. This presents a dilemma: the ease of a spray versus the long-term health of certain leathers. Sprays are generally better suited for more delicate surfaces like suede, nubuck, or even textiles, where creams or waxes would be inappropriate.

Myth #3: Any Waterproofing Treatment Will Suffocate Leather and Ruin Its Breathability. Not necessarily. While it’s true that some heavy treatments or certain silicone-based sprays can indeed reduce leather’s natural breathability by clogging its pores , this isn’t a universal outcome. Many modern waterproofing methods, including high-quality waxes, conditioning creams, and advanced technologies like Gore-Tex membranes, are engineered to provide substantial water resistance while still allowing for a good degree of breathability. The key is selecting the right method appropriate for the specific leather type and the product’s intended use. It’s about smart choices, not blanket avoidance.

Myth #4: Once Waterproofed, Leather Needs No Further Attention. Waterproofing is not a magical, one-time, permanent fix. Think of it as a protective layer that, like any shield, can wear down with use, exposure to the elements, and even cleaning. Regular maintenance and reapplication of the waterproofing treatment are absolutely crucial. This maintains effective protection and the leather’s overall condition. Leather is a dynamic material that interacts with its environment; its care must be an ongoing commitment, not a single action.

Myth #5: You Can Use Household Products (Like Hair Spray or Olive Oil for Cooking) to Waterproof Leather. This is generally a very bad idea and can cause irreversible damage. Household products are not formulated for the complex chemistry of leather. Hair spray, for example, often contains alcohol and polymers that can severely dry out and damage the leather surface. While olive oil is sometimes mentioned in DIY waterproofing recipes , these typically specify extra virgin olive oil and always in combination with other ingredients like beeswax, in carefully measured proportions. Using straight cooking oil is likely to lead to rancidity, attract dirt, cause uneven absorption, and potentially stain the leather. Always stick to products specifically designed and tested for leather care.

Chapter 3: Know Your Hide: Why Leather Type Dictates Your Waterproofing Strategy

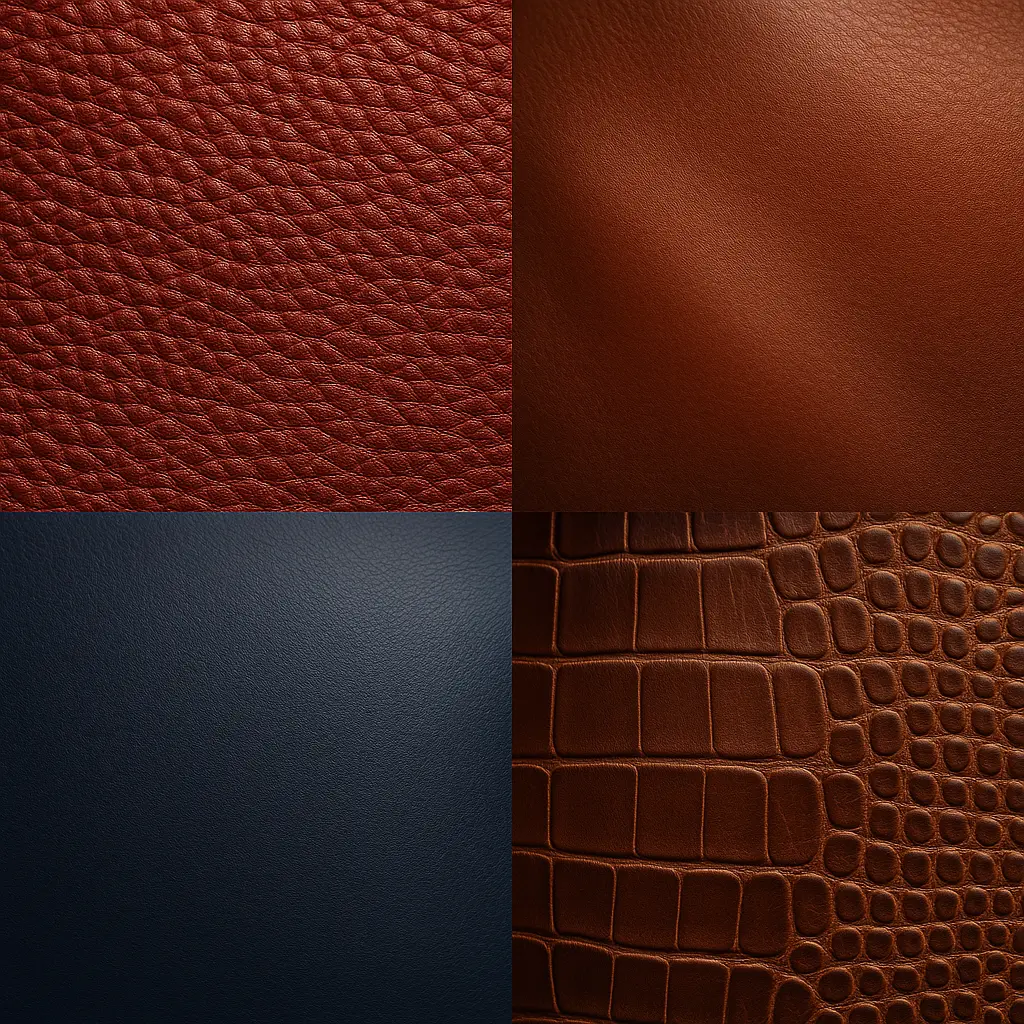

Not all leather is created equal. Its origin, the animal it came from, the tanning process it underwent, and the final finish applied all dramatically affect its inherent characteristics. This is particularly true for its porosity and how it will react to water and any waterproofing treatments. Choosing a waterproofing method without considering the specific leather type is like prescribing medicine without a diagnosis – it can do more harm than good.

The finish applied at the tannery, such as aniline, semi-aniline, or pigmented, is just as important as the grain type, like full-grain or top-grain. Aniline finishes, for instance, leave the leather’s pores more open. This enhances natural beauty but also increases susceptibility to moisture. Pigmented finishes, on the other hand, create more of a surface coating. This nuance means that even within a category like “full-grain,” the specific finish warrants consideration for an optimal waterproofing strategy.

Let’s break down the common leather types and the best approaches for each.

Full-Grain Leather This is the highest quality and most durable leather, made from the outermost layer of the hide. It retains the natural grain, imperfections, and character of the animal skin. Its dense fiber structure gives it a degree of natural water resistance. For full-grain leather, waxes and creams are generally the preferred methods. These products provide a protective barrier against moisture and also nourish and condition the leather. This keeps it supple and helps develop a beautiful patina over time. It’s wise to avoid heavy silicone sprays, as these can create a surface film that blocks the absorption of nourishing ingredients, potentially leading to dryness and cracking. Natural oils like pure neatsfoot oil or mink oil can be used, but with caution, as they are potent and can significantly darken the leather. DIY beeswax formulations are also a viable option. This leather is ideal for durable footwear like premium work boots, classic equestrian gear, or luxury handbags where longevity and a rich patina are valued.

Top-Grain Leather The second-highest quality, top-grain leather has had its outermost layer of imperfections sanded off and a finish coat applied. This makes it smoother and more uniform than full-grain, but slightly less durable as some strong fibers are removed. Similar to full-grain, creams, lotions, and some carefully selected non-silicone sprays can be effective. Due to its refinished surface, top-grain leather often requires more frequent treatment than full-grain to maintain its protection and appearance. Always perform a patch test in an inconspicuous area, as the finish can react differently. It’s commonly found in fashion accessories, quality upholstery, and car interiors, benefiting from treatments that protect its smooth finish.

Suede & Nubuck These leathers are prized for their soft, napped, velvety surface. Suede is made from the underside of the animal skin (or a split), while nubuck is created by sanding the grain side of top-grain leather. Both are very porous and highly susceptible to water damage, staining, and matting. Suede and nubuck require a different waterproofing mindset. Specialized waterproofing sprays designed explicitly for them are essential. These sprays repel water and stains without matting the delicate nap or significantly altering the color. Avoid waxes and heavy creams at all costs, as these will ruin their texture. Think of delicate suede loafers or nubuck hiking boots; they need a gentle yet effective shield.

Patent Leather Patent leather is distinguished by its high-gloss, mirror-like finish, achieved by applying a coating of lacquer, polyurethane, or acrylic. This coating makes it inherently very water-resistant, if not virtually waterproof. Generally, patent leather does not require additional waterproofing treatments. Care should focus on cleaning the glossy surface. Classic patent leather pumps or a sleek trench coat are already well-equipped for a drizzle.

Bonded Leather / Faux Leather (PU Leather) It’s important to distinguish these from genuine hide. Bonded leather is made from leftover leather scraps and fibers bonded with polyurethane or latex onto a backing. Faux leather (PU leather or vegan leather) is entirely synthetic, typically a plastic base like polyurethane coated onto fabric. These materials are not true leathers. Faux leather is usually waterproof due to its plastic nature. Bonded leather might offer minimal water resistance from its coating, but its durability is limited. If treatment is considered for bonded leather, a light spray for synthetics might be used, but expectations should be managed. Their care and properties differ greatly from genuine leather, often found in fast-fashion or budget furniture.

Expert Tip: Identifying Your Leather

Not sure what type of leather you’re working with? Here are a few quick pointers.

First, look at the grain. Full-grain leather will show natural markings, pores, and minor imperfections – the authentic story of the hide. Top-grain leather will have a more uniform, smoother surface because it’s been corrected. Suede and nubuck have a distinct matte, velvety feel with a visible nap. Patent leather is unmistakable with its high-gloss, reflective shine.

Next, feel the texture. Genuine leather, especially full-grain, often feels supple, warm, and has a unique texture. Faux leather can feel plasticky, cold, or unnaturally uniform.

Don’t forget the smell test. Real leather has a characteristic, rich, natural odor. Faux leather or heavily treated low-quality leathers may smell of chemicals, plastics, or have no discernible scent.

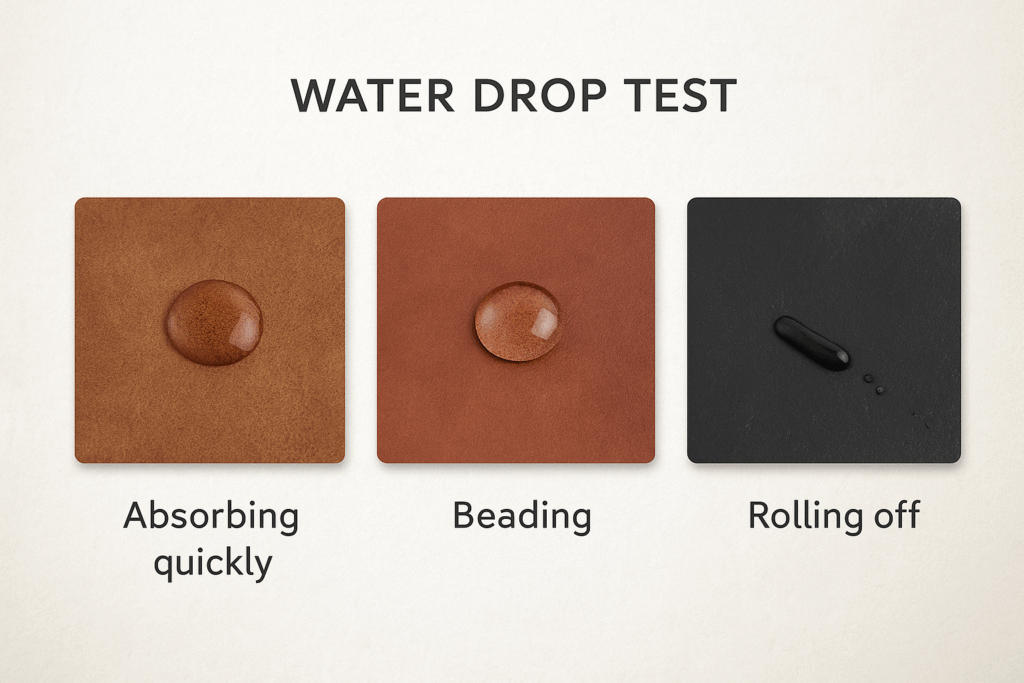

Finally, consider the water drop test, but use it with caution on untreated items. On a small, hidden spot of an untreated leather item, place a single drop of water. If it soaks in quickly and darkens the spot, the leather is likely quite porous, common for suede, nubuck, or some unfinished aniline full-grains. If the water droplet beads up and sits on the surface for a while before slowly being absorbed, it has some natural water resistance, typical of good quality full-grain or top-grain. If it rolls right off, it might already be treated or be a non-porous material like patent or faux leather.

Chapter 4: The Arsenal: Choosing Your Weapon – Waterproofing Products & Technologies

Once you’ve identified the type of leather, it’s time to select the right protective treatment. The market offers a diverse arsenal, from traditional topical applications to advanced built-in solutions. Each has its unique mechanism, benefits, drawbacks, and ideal scenarios.

It’s helpful to think about protection in two broad categories: treatments applied by the consumer after the product is made (“outside-in” protection) and waterproofing integrated during manufacturing (“inside-out” protection). This difference impacts durability, breathability, and maintenance.

A. Consumer-Applied Treatments: Your First Line of Defense

These are products you can apply at home to enhance or restore water resistance.

Waterproofing Sprays Sprays work by creating a protective, hydrophobic barrier on the leather’s surface. This causes water to bead up and roll off rather than soak in. Formulations vary; some use fluoropolymers, others silicone, and newer types may use different technologies.

One of the main advantages is their convenience and speed; they are excellent for achieving an even application over large or complex surfaces with minimal effort. Sprays are often the go-to choice for suede and nubuck, as they can provide protection without matting the nap or significantly altering the texture, which creams or waxes would do. Some modern sprays are also formulated to maintain a degree of leather breathability.

However, there are drawbacks. A significant concern with some sprays, especially silicone-based ones, is their potential to form an impermeable film on full-grain leather. This film can prevent nourishing oils from conditioners from penetrating, leading to the leather drying out from the inside over time. The protective effect of sprays can also be less durable than that of waxes or creams, often requiring more frequent reapplication, especially on items that see heavy use. Tsuchiya Kaban, for example, suggests weekly reapplication for daily-use bags in rainy weather. Some older or cheaper formulations might negatively impact breathability or contain Volatile Organic Compounds (VOCs); looking for VOC-free options is worthwhile.

Sprays are best for suede, nubuck , quick protection on certain types of finished leathers (after a successful patch test), and even some textiles.

Expert Tip: “Always choose a spray specifically formulated for your leather type. If considering a spray for smooth leathers, investigate newer non-silicone formulations that are less likely to impede future conditioning. Good ventilation during application is non-negotiable for safety and to avoid inhaling fumes.”

Waxes & Creams These products typically penetrate the leather to some degree, conditioning the fibers from within, while also forming a more substantial, water-resistant barrier on the surface. Waxes often contain natural components like beeswax or carnauba wax, or sometimes paraffin. Creams are usually emulsions of oils and waxes, offering both protection and conditioning.

The advantages include robust and durable protection; they generally provide a stronger and longer-lasting barrier against water compared to sprays. They also offer significant conditioning benefits, helping to keep the leather supple, nourished, and preventing it from drying out and cracking.

As for disadvantages, they are more labor-intensive to apply evenly than sprays, requiring careful rubbing and sometimes buffing. Waxes and some creams, especially those with high natural wax content, can darken the leather or alter its sheen, particularly on lighter colors. A patch test is essential. They may also slightly reduce breathability compared to untreated leather, though often less significantly than heavy silicone sprays. Waxes and creams are unsuitable for suede or nubuck as they will mat the nap.

These are best for full-grain and top-grain leathers, especially on items facing harsh conditions like work boots, outdoor bags, and equestrian gear.

Natural Oils (Mink Oil, Neatsfoot Oil) These traditional conditioners are potent and require careful consideration.

Mink Oil, derived from mink fat, is rich in palmitoleic acid, allowing it to penetrate leather fibers deeply to condition and impart water resistance. Its advantages are that it’s an excellent conditioner that softens leather, enhances flexibility, and provides good water resistance, often used for rugged items like work boots. However, its disadvantages include significantly darkening leather, especially lighter shades. Over-application may leave an oily residue. There are also some debated concerns about long-term heavy use clogging pores or weakening fibers, and potential ethical considerations regarding its origin.

Neatsfoot Oil is rendered from the shin bones and feet of cattle. Pure neatsfoot oil is valued for replenishing natural oils, conditioning, and softening leather. Its advantages include effectively softening stiff leather and providing some water resistance. The disadvantages are that it’s also known to darken leather noticeably. It’s crucial to distinguish between “pure neatsfoot oil” and “prime neatsfoot oil” or compounds, as the latter may contain petroleum additives that can degrade leather. Pure neatsfoot oil is preferred and can leave an oily residue that attracts dust if not fully absorbed.

Expert Tip: “Natural oils like mink and pure neatsfoot oil are powerful. Use them sparingly, always opt for ‘pure’ versions, and be prepared for distinct color darkening. They are generally best for heavy-duty workwear or restoring very dry leather, less so for fine fashion items where original color is paramount.”

DIY Beeswax Formulations A popular DIY approach involves melting beeswax (often 1 part) with a natural oil like extra virgin olive oil or coconut oil (often 2-3 parts), then cooling it into a balm. A common recipe suggests 1 cup of extra virgin olive oil to 2 ounces of beeswax, gently heated until melted, then stirred continuously while cooling to achieve a smooth texture. This balm is applied to clean leather, worked in, allowed to soak, and then buffed.

The advantages include using natural ingredients, being cost-effective, and allowing customization. The disadvantages are that results can be variable. There’s potential for uneven application or residue if not made carefully, and like other natural waxes, it may darken the leather. It also requires more preparation effort.

B. Advanced Solutions: Built-In Protection

These are waterproofing technologies typically integrated during manufacturing.

Tannery-Level Waterproofing (Hydrophobic Leathers) This advanced approach achieves water resistance more fundamentally. During the retanning process in the tannery, specialized waterproofing agents like waterproof fatliquors, silane coupling agents, or silicone oils are incorporated. These agents fill microscopic interstices or make fibers hydrophobic. For example, one method uses Meropol Oil WPS and Meropol Oil WP Top , while another focuses on environmentally friendlier silane coupling agents to crosslink collagen fibers.

This method generally offers more integral and durable water resistance than surface treatments. The leather itself is engineered to repel water and can also see improvements in physical properties like tensile and tear strength. The waterproof level is often rigorously tested using metrics like the Maeser flex test, which measures flexes under wet conditions before penetration. The U.S. Military standard for some applications is 15,000 Maeser flexes. Well-executed tannery waterproofing aims for a balance, resulting in leather that is water-resistant yet maintains softness, a tight grain, and a pleasant handle. This is ideal for high-performance footwear, sports gear, and applications needing robust, long-lasting water resistance.

Waterproof Membranes (e.g., Gore-Tex®, other ePTFE brands) This technology involves laminating a microporous membrane – famously expanded polytetrafluoroethylene (ePTFE) for Gore-Tex – typically between the outer leather and inner lining of a product. The membrane’s pores are about 20,000 times smaller than a water droplet, blocking external water, yet 700 times larger than a water vapor molecule, allowing sweat to escape. This dual action makes these membranes both waterproof and breathable.

The primary advantages are excellent waterproofness AND breathability, and products are also typically windproof. Membranes can be part of 2-layer, 2.5-layer, or 3-layer constructions, each affecting weight, warmth, and durability. To ensure integrity, seams are typically sealed with special tape. Crucially, even with a membrane, the outer leather is often treated with a Durable Water Repellent (DWR) finish. This DWR causes surface water to bead off, preventing the outer leather from “wetting out,” which would impede the membrane’s breathability. This DWR coating needs periodic maintenance. This technology is ideal for outdoor footwear, technical apparel, gloves, and gear where dryness from both external and internal moisture is critical.

Key Considerations When Choosing Your Waterproofing Method:

When selecting your waterproofing method, several factors come into play. As extensively detailed in Chapter 3, the leather type is your primary guide. Consider the item’s intended use: is it for rugged outdoor adventures or an occasional fashion piece?

Think about the desired aesthetics. Are you concerned about potential color changes, like darkening? Is maintaining a specific finish, such as matte versus a slight shine, important? For instance, matt smooth leather should not be treated with leather grease or wax, as this will alter its appearance.

Breathability needs are especially crucial for footwear and clothing to ensure comfort. Finally, consider the maintenance effort. How often are you willing to reapply the treatment? Some methods are longer-lasting but more involved, while others are quick but require frequent attention.

To help you navigate these options, here’s a quick comparison:

Waterproofing Methods at a Glance

| Method | Primary Mechanism | Best For Leather Types | Key Pros | Key Cons | Impact on Breathability | Typical Reapplication |

|---|---|---|---|---|---|---|

| Silicone Spray | Surface film | Suede, Nubuck, some synthetics | Convenience, quick application | Can block nourishment in full-grain, may reduce breathability significantly | Can reduce significantly | Frequent (weeks) |

| Non-Silicone Spray | Surface film (often more breathable) | Suede, Nubuck, some finished leathers | Convenience, often better for breathability than silicone | May be less durable than waxes/creams | Minimal to moderate reduction | Frequent (weeks to months) |

| Wax | Penetrates slightly & surface barrier | Full-grain, Top-grain (especially rugged) | Durable protection, conditions | Labor-intensive, can darken leather, not for suede/nubuck | Moderate reduction | Moderate (months to a year) |

| Cream | Penetrates & conditions, light surface barrier | Full-grain, Top-grain | Conditions well, good protection | Can darken leather, may be less robust than pure wax, not for suede/nubuck | Minimal to moderate reduction | Moderate (months) |

| Mink Oil (Pure) | Deep penetration & conditioning | Rugged Full-grain (e.g., work boots) | Excellent conditioner, softens, good water resistance | Significantly darkens leather, oily, ethical concerns for some | Can reduce if over-applied | Moderate (months) |

| Neatsfoot Oil (Pure) | Deep penetration & conditioning | Dry/Stiff Full-grain (restoration, rugged) | Softens, restores oils | Significantly darkens leather, oily residue, “compound” versions harmful | Can reduce if over-applied | Moderate (months) |

| DIY Beeswax Balm | Penetrates slightly & surface barrier (natural) | Full-grain, Top-grain | Natural ingredients, customizable | Variable results, can darken, effort to make | Moderate reduction | Moderate (months) |

| Tannery Treatment | Hydrophobic fibers (integral to leather) | Leathers designed for high performance | Highly durable, integral, can improve physicals, often breathable | Part of initial manufacturing (higher product cost), not a DIY option | Generally good (designed for it) | Long-lasting / None (integral) |

| Membrane (e.g, Gore-Tex) | Microporous barrier (laminated layer) | Items needing high waterproof/breathability | Excellent waterproofing & breathability, windproof | Part of product construction (higher cost), outer DWR needs maintenance | Excellent (membrane is breathable) | Long-lasting / None (membrane) |

Export to Sheets

This table provides a snapshot, but always refer to product-specific instructions and consider the unique needs of your leather item.

Chapter 5: The Art of Application: Step-by-Step Guide to Waterproofing Your Leather

Applying a waterproofing treatment isn’t just about slapping on a product. The right technique is crucial for effectiveness, even coverage, and protecting your valuable leather. Meticulous preparation and patient application are hallmarks of professional-level care.

Here’s a step-by-step guide.

Step 1: Clean Your Leather Thoroughly – The Non-Negotiable First Step Applying any waterproofing product onto a dirty surface is a recipe for failure. Dirt, grime, dust, and oils can act as a barrier, preventing the agent from adhering properly or penetrating evenly. You’d essentially be sealing dirt into the leather.

For cleaning, start by removing loose surface dirt with a soft brush or a clean, dry microfiber cloth. For smooth leathers like full-grain or top-grain, then use a quality leather cleaner. Apply a small amount to a soft cloth and work it in using gentle, circular motions. Avoid harsh soaps or detergents. Suede and nubuck require a specialized suede/nubuck brush to lift dirt and restore the nap; a suede eraser can be used for stubborn spots. After cleaning, allow the leather to air dry completely and naturally in a well-ventilated area at room temperature. Avoid direct heat sources like hairdryers or sunlight, as this can cause cracking.

Step 2: The Patch Test – Always Test First! This vital precautionary step should never be skipped. Waterproofing products can alter color, texture, or leave an unexpected finish. A patch test identifies adverse reactions on a small, hidden area before treating the entire item.

Choose an inconspicuous spot like an inner seam, under a flap, or an inside facing. Apply a small amount of your chosen product, following the intended application method. Allow it to dry completely according to instructions. Once dry, examine for discoloration, staining, or undesirable texture changes. If it looks good, proceed. If not, you’ve saved your item.

Step 3: Application Techniques by Product Type – Precision Matters The “less is more” principle often applies; over-application rarely improves protection.

For sprays, always work in a well-ventilated area. Hold the can about 6-8 inches (15-30 cm) from the surface. Apply in thin, even coats with a sweeping motion, avoiding saturation. Two or three light coats are better than one heavy coat. Pay particular attention to seams and stitching.

For creams and waxes, apply a small amount of the cream or wax to a clean, soft cloth or fingertips. Rub gently into the leather using circular motions for even distribution and absorption. Allow time for absorption. Depending on the product, it may then require buffing with a clean, dry cloth to remove excess and enhance shine.

For oils and DIY balms, apply sparingly with a soft, clean cloth. Work it in evenly. Gently warming pure neatsfoot oil can improve penetration, but apply with a cloth, not directly. Allow ample time for absorption, then consider a light buffing.

Step 4: Drying Done Right – Patience is a Virtue This stage is crucial. The product needs time to cure and bond. Rushing can lead to a tacky finish or ineffective treatment.

Allow the treated item to air dry naturally in a cool, dry, well-ventilated area at room temperature. Never use direct heat like sunlight, heaters, or hairdryers, as this can cause stiffness, brittleness, or cracking. Drying time varies by product, application thickness, leather type, and ambient conditions. Sprays might feel dry in 20-60 minutes but need longer to cure. Waxes, creams, and oils typically require several hours or overnight. Some experts recommend 24 hours for optimal protection. Always refer to your product’s label.

Step 5: Testing Effectiveness – Did it Work? Once completely dry and cured, test the treatment. Sprinkle a few drops of clean water onto a treated area.

If successful, water droplets should bead up and remain on the surface or roll off easily without soaking in. This indicates a hydrophobic barrier. If water darkens the leather or soaks in, the treatment may be insufficient, unsuitable, or need another light application after drying.

Chapter 6: Maintaining the Shield: Long-Term Care for Waterproofed Leather

Applying a waterproofing treatment is significant, but it’s not a “set it and forget it” solution. Ongoing care is essential to ensure that protective shield remains effective and your leather stays at its best. Waterproofing enhances resilience but doesn’t negate the need for regular attention.

Regular Cleaning: The Foundation of Lasting Protection Even expertly waterproofed leather accumulates dust and grime. These particles can be abrasive, degrading the treatment and the leather over time. Routinely wipe items with a soft, dry cloth. For more thorough cleaning, use a cleaner appropriate for your leather type and compatible with its waterproofing, cleaning gently without stripping the protective layer. Avoid harsh chemicals, solvents, or abrasive soaps.

Conditioning (If Applicable): Balancing Protection with Nourishment This is crucial for full-grain and top-grain leathers, especially those treated with conditioning waxes or creams. While these products condition, the leather may still need dedicated conditioning over time to maintain suppleness and prevent dryness or cracking. A challenge arises because some waterproofers, particularly certain sprays, can hinder conditioner penetration.

Expert Tip: “If you’ve used a wax-based waterproofer, it likely contains conditioning agents, so additional conditioning might be needed less frequently. For items treated with sprays (especially non-silicone versions) or if leather feels dry, use a compatible leather conditioner. Apply sparingly after cleaning.” It’s about balancing protection with essential moisture.

Reapplication Frequency: How Often is Enough? The durability of waterproofing is finite, depending on the product type, usage level, and environmental exposure. Generally, sprays require more frequent reapplication (every few weeks to a couple of months for regular use , or even weekly in rainy seasons ) than waxes or creams (every few months to once or twice a year , though one robust wax application might last years with light wear ). Items used frequently or in harsh conditions need more attention.

Key signs it’s time to reapply include water no longer beading effectively and instead soaking in , visible wear of the protective layer, or the leather appearing dull or dry.

Expert Tip: “Don’t wait for visible water damage. Proactive reapplication based on usage and visual cues is key. If you anticipate heavy use in rain, refresh the treatment beforehand.”

Proper Storage Tips: Protecting Your Leather When Not in Use Store leather goods in a cool, dry, well-ventilated place. Avoid plastic bags or airtight containers; leather needs to “breathe” to prevent mold. Use breathable fabric dust bags. Keep items away from direct sunlight and extreme heat, which can degrade leather and its treatment.

An Important Consideration: Impact on Patina Development For many, especially those with vegetable-tanned full-grain leather, the development of a rich patina is highly desirable. Patina is the sheen and darkening from aging and absorbing oils and sunlight. Be aware that some heavy waterproofing treatments might slow down or alter this natural patination process by limiting absorption. Some suggest waterproofing can prevent dirt settling, which also affects patina. For those prioritizing patina, scheduling waterproofing based on weather forecasts rather than constant heavy sealing might be strategic. Lighter, more breathable treatments are generally more conducive to natural aging.

By incorporating these long-term care practices, you ensure lasting benefits from your waterproofing efforts.

Chapter 7: Waterproofing and Breathability: Finding the Right Balance

One of leather’s most valued qualities, especially for items like footwear, gloves, and apparel, is its natural breathability. Genuine leather allows air and moisture vapor (like perspiration) to pass through, contributing to comfort by regulating temperature and reducing moisture buildup. But how do waterproofing treatments affect this?

Leather “breathes” due to its complex, fibrous structure with countless microscopic pores and interfiber spaces, allowing air and water vapor exchange. The tanning process influences this; vegetable tanning tends to leave pores more open than some chrome tanning processes. Generally, full-grain leather is more breathable than heavily treated or coated leathers.

[Image: A microscopic-style illustration showing the porous structure of leather with arrows indicating air and moisture vapor passing through.]

The impact of waterproofing on breathability varies. Heavy coatings and finishes, common in some patent or corrected grains, can significantly reduce breathability by creating an impermeable film that blocks pores. Many common silicone-based waterproofing sprays can also compromise breathability by forming a continuous film over the leather surface, which, while effective at repelling water, may also seal the pores and prevent moisture vapor from escaping.

Waxes and creams typically penetrate the leather’s surface to some extent while also forming a protective layer on top. They can reduce breathability compared to untreated leather, but generally, the impact is less severe than with impermeable films or heavy silicone coatings. The specific formulation (e.g., natural waxes like beeswax are often considered more breathable than synthetic sealants) and the thickness of application play a significant role. A light, even application is less likely to suffocate the leather. Natural oils like mink or neatsfoot oil, if over-applied, can saturate the leather and potentially reduce breathability by clogging the interfiber spaces with excess oil.

Modern advancements in tannery waterproofing are increasingly focused on creating leathers that are inherently water-resistant without a major sacrifice in breathability. Processes that use specialized waterproof fatliquors or agents like silane coupling compounds aim to make the individual leather fibers hydrophobic (water-repelling) rather than just coating the surface. Some of these advanced systems are reported to maintain good, or even improved, vapor permeability, indicating a conscious effort to preserve breathability. This shows that the industry is innovating to address the traditional trade-off.

Waterproof membranes like Gore-Tex® are where technology truly shines in balancing these properties. Membranes like Gore-Tex are specifically engineered to be both waterproof and highly breathable. As discussed earlier, their microporous structure blocks liquid water from entering from the outside but allows smaller water vapor molecules (perspiration) to escape from the inside. This “system” approach, where the membrane handles the core waterproofing and breathability, is a key advantage for activewear, outdoor gear, and all-weather footwear where managing moisture from both internal and external sources is critical for comfort. Remember, for these systems to work optimally, the outer leather layer should also be maintained with a DWR treatment to prevent it from becoming saturated, as a waterlogged outer layer can impede the membrane’s ability to breathe effectively.

Expert Tip: Prioritizing Breathability in Your Choices

“For leather items that are worn close to the body for extended periods – especially shoes, boots, gloves, and jackets – prioritizing breathability is absolutely key to user comfort. If maximum performance in demanding weather conditions is required, consider products that feature integrated breathable waterproof membranes like Gore-Tex or similar technologies. When using topical waterproofing treatments on such items, opt for non-silicone sprays, high-quality creams, or natural waxes that are known for maintaining better breathability. Always apply these products sparingly and evenly. When sourcing leather, look for options that have been tannery-treated for water resistance using modern technologies that also explicitly consider and aim to preserve vapor permeability.”

Achieving effective water resistance in leather doesn’t have to mean completely sacrificing its natural comfort and breathability. It’s a balancing act that involves understanding the properties of different leather types, the mechanisms of various waterproofing treatments, and making choices that are appropriate for the item’s intended use. Modern material science and thoughtful application can help achieve an optimal equilibrium.

Chapter 8: Smart Buying: Identifying Quality Waterproofed Leather Goods

When investing in a leather product marketed as “waterproof” or “water-resistant,” how can you, as a designer, developer, brand, or discerning consumer, ensure you’re getting genuine quality and truly effective protection? It’s not just about the claim; it’s about the substance behind it. Effective waterproofing is a component of a high-quality item, not its sole determinant; the entire product must be considered.

First, look for clarity and honesty in terminology. Does the brand clearly and accurately state how the water resistance is achieved? Look for specific descriptions like “treated with a durable water-resistant (DWR) finish,” “features an integrated Gore-Tex waterproof-breathable membrane,” or “crafted from hydrophobic tanned leather.” Vague, unsubstantiated claims of “waterproof” are a red flag. Transparency here is often a proxy for brand trustworthiness.

The type and quality of base leather are fundamental. High-quality base leather (e.g., full-grain or top-grain) is essential. Applying a waterproofing treatment to a poor-quality, weak, or inherently flawed leather won’t magically transform it into a durable, premium product. The waterproofing should enhance good leather, not try to compensate for bad leather.

Investigate the method of waterproofing. If it’s a tannery treatment (hydrophobic leather), brands that are proud of their quality may provide information about the technology used or performance standards met (e.g., Maeser flex rating for heavy-duty items, indicating durability of the waterproofness under stress ). If an integrated membrane is used, look for reputable, proven brands like Gore-Tex, eVent, or others known for their waterproof-breathable technology. If it’s a topical finish applied post-manufacture by the brand, try to understand what kind of treatment was used and what its expected durability and maintenance requirements are.

Examine the construction: stitching and seams. For maximum water resistance, especially in items like footwear and outerwear, look for designs with minimal seams in critical areas that are prone to water entry. Furthermore, are the seams sealed? High-quality waterproof construction often involves taping or sealing seams. A high stitch count per inch (e.g., 7-8 SPI) can also be an indicator of quality craftsmanship and durability.

Hardware quality is also important; zippers, buckles, snaps, and other hardware should be of high quality and rust-resistant. Moisture can affect these components too, and failing hardware can compromise the product long before the leather does. A quality lining material, for items like bags, jackets, or shoes, contributes to the overall integrity, comfort, and longevity of the product.

Consider the brand reputation and transparency. Reputable brands are generally more transparent about their materials, sourcing, and manufacturing processes. Crucially, do they provide clear, comprehensive care instructions for maintaining the product’s water resistance and overall condition? This shows a commitment to the product’s long-term performance. Finally, assess “fitness for purpose”: the level and type of waterproofing should align with the product’s intended use. A sophisticated dress shoe doesn’t require the same extreme Maeser flex rating as a military combat boot.

Be wary of red flags. These include over-reliance on the single word “waterproof” without any supporting details or explanation of the method used. Also, watch out for the use of low-quality base leather (e.g., bonded leather or very thin, poorly finished splits) marketed as highly water-resistant without a clearly robust and durable coating or technology. Evidence of poor construction, such as gappy or uneven seams, loose threads, or cheap, flimsy hardware, is another warning sign. Lack of clear care instructions for maintaining waterproof properties should also raise concern.

Expert Tip: Engage with the Brand

“Don’t just take a ‘waterproof’ label at face value. If you’re serious about quality and performance, ask questions. Inquire how the product is waterproofed and what specific maintenance is recommended to preserve that quality. A quality manufacturer or knowledgeable retailer will be happy to explain their processes and materials. This dialogue not only gives you valuable information but also demonstrates their commitment to product performance, durability, and customer satisfaction.”

By being an informed buyer or a transparent producer, you contribute to a market where quality and genuine performance are valued.

Chapter 9: DIY vs. Professional Waterproofing: When to Call in the Experts (For Leather Goods Care)

While many routine leather waterproofing tasks can be effectively managed at home, there are situations where entrusting your valuable leather goods to a professional leather care specialist might be wiser. The decision often hinges on the value and complexity of the item versus your confidence and the potential cost of a DIY mistake. This section adapts logic from home maintenance to leather care.

DIY Leather Waterproofing: The Home Approach This approach offers cost savings as you only pay for products, not labor. It’s customizable, allowing you to tailor applications, and offers a sense of accomplishment. It’s also convenient, fitting your schedule. DIY is best for regular maintenance of common items like everyday shoes and bags, using consumer products where application is straightforward, or for minor touch-ups when you understand the leather and products.

However, there’s a risk of error. Using the wrong product or applying it incorrectly can lead to discoloration, damage, or ineffective waterproofing, potentially costly to reverse. It also requires a time commitment for cleaning, application, and drying. While you save on labor, quality products are an expense. DIY treatments may also offer less durability than professional or tannery treatments.

Professional Leather Care Services (for Waterproofing, Cleaning & Restoration) These are specialist cobblers or leather restoration experts. They possess in-depth knowledge and experience, accurately diagnosing issues and selecting the best treatments. Professionals use higher-strength or specialized products and equipment not typically available to consumers, potentially achieving more effective or durable results. They are better equipped for very expensive, delicate, exotic, or vintage items where DIY risk is high. They can also address other issues like stains or repairs simultaneously. Some services may offer guarantees.

Professional care is best for high-value items like designer handbags or bespoke shoes, vintage or heirloom pieces needing careful restoration, items with stubborn stains or existing damage, or if you lack time, confidence, or knowledge. Specialized technical gear might also benefit from expert handling.

The downsides include higher cost due to labor and expertise. There’s also turnaround time, meaning you’ll be without your item. Finding a reputable professional may require research.

Expert Tip: Making the Call

“For routine care of standard leather goods, a well-informed DIY approach with quality products is manageable. Follow procedures for cleaning, patch testing, application, and drying. However, for high-value heirlooms, delicate leathers, items with significant damage, or specialized technical gear, consult a reputable professional. They can ensure the job is done correctly, preserving your item’s function and beauty.”

It’s important to distinguish these “professional leather care services” from “tannery-level waterproofing.” Tannery treatments are part of initial manufacturing; these services are for post-purchase care.

Chapter 10: Conclusion: Investing in Protection, Investing in Longevity

We’ve journeyed through the world of leather waterproofing, from “water-resistant” vs. “waterproof” to treatments and application. This knowledge is fundamental to creating, selling, and enjoying high-quality leather goods that last.

Core Takeaways: True “waterproofing” in leather is rare; the aim is excellent water resistance. Myth-busting is essential; misconceptions about sprays on full-grain leather can cause damage. There’s no one-size-fits-all solution; leather type dictates the method. The application process is as critical as the product. Meticulous cleaning, patch testing, even application, and correct drying are key. Waterproofing is an ongoing commitment, requiring regular cleaning, conditioning, and reapplication. Leather’s breathability can be balanced with water resistance through smart choices like advanced tannery treatments, membranes, or suitable topical products.

Why This Knowledge Matters: For designers, product developers, and brands, this understanding allows selection of right leathers and treatments, engineering higher-quality goods, providing accurate care info, and building a reputation for excellence. For knowledgeable consumers, it empowers informed purchasing, proper care for longevity, and avoidance of damaging practices.

A Final Thought: Leather is remarkable – durable, beautiful, and capable of developing character. Correctly protecting it from elements means investing in its story, performance, and longevity. Choose methods wisely, care diligently, and your leather will reward your efforts for years.

Ready to Elevate Your Leather Care or Product Line?

- Explore our curated range of expertly formulated, all designed to provide superior protection and nourishment for your finest leather goods.

- Are you a designer or brand embarking on a new collection, or do you need expert advice on selecting the optimal leathers and treatments for your specific product requirements? Contact our dedicated leather experts today!

- Want to delve deeper into the world of leather? Check out our other insightful articles