Ever felt confused navigating the world of leather? Terms like suede, nubuck, and split leather get thrown around, but what do they really mean for the quality, durability, and feel of your products? You’re definitely not alone.

Choosing the right type of leather is absolutely critical. It impacts everything from how a shoe flexes to how a bag ages to how comfortable a jacket feels. Get it wrong, and you could end up with a product that disappoints. Get it right, and you create something truly special.

As leaders in crafting high-quality leather goods, we’ve spent decades working hands-on with these materials. We live and breathe the nuances that separate merely good leather from great leather. We understand the journey from raw hide to finished product and know precisely how each step influences the final outcome.

In this guide, we’re pulling back the curtain. Get ready to discover the key differences between suede, nubuck, and split leather – how they’re made, their unique characteristics, and where each truly shines. Plus, we’ll share insider tips on how to identify each type like a pro and care for them correctly.

Let’s dive in.

Why Getting Your Leather Types Right is CRUCIAL for Quality

Think of leather manufacturing like building a house. The foundation you choose dictates the strength and longevity of the entire structure. Similarly, understanding the source (which part of the animal hide is used) and the processing (how it’s tanned and finished) is fundamental to the final leather product’s performance, appearance, and lifespan.

It goes far beyond just the surface look. Selecting an inappropriate leather type can lead to real problems down the line. Imagine using delicate suede for a rugged backpack destined for daily commutes – it simply won’t hold up. Likewise, using a stiff, less pliable leather for intricate design work can frustrate manufacturers and compromise the final design.

Of course, there’s the cost factor. Different leather types come with different price tags, reflecting the raw material quality and processing complexity. Knowing the inherent properties and trade-offs of suede versus nubuck versus split leather allows you, whether you’re a designer, manufacturer, or consumer, to make informed decisions that balance your budget with the desired quality and performance.

Ultimately, understanding these distinctions helps set the right expectations. For designers and brands, it ensures you’re selecting the optimal material for your intended application. For consumers, it empowers you to know what you’re actually buying, appreciate its unique qualities, and understand how to care for it properly.

One critical reason this knowledge is vital relates to industry terminology itself. Terms like “Genuine Leather” might sound premium, suggesting authenticity and high quality. However, in the leather industry, this label often specifically refers to split leather – the lower, less durable layer of the hide. Because split leather lacks the dense top grain, it doesn’t possess the same strength or longevity as full-grain or top-grain leather. An uninformed buyer might see “Genuine Leather” and assume they’re getting a top-tier product, when the term actually denotes a specific, lower grade. This potential gap between perception and reality underscores why clear, accurate information about leather types is essential for everyone involved.

Suede Explained: The Velvet Touch

Let’s start with one of the most recognizable leather types, known for its signature softness.

What Exactly Is Suede? (Definition & Origin)

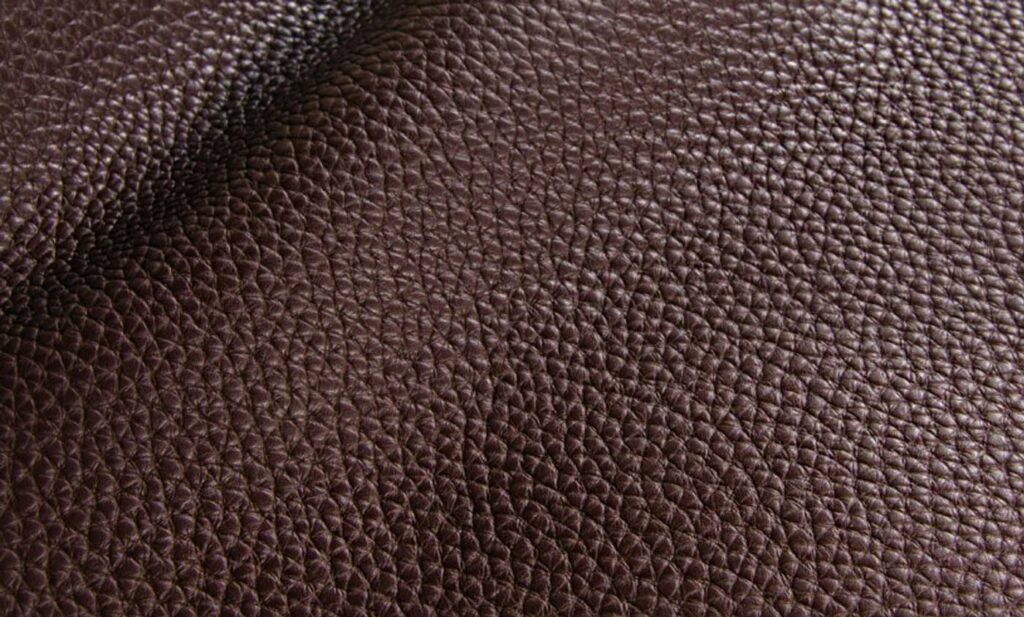

Suede is a type of leather easily identified by its soft, fuzzy, napped surface. Think velvet, but made from leather.

Crucially, it’s created from the underside (or flesh side) of the animal hide. When a hide is split into layers, the top part (with the outer skin) becomes grain leather, while the inner, more fibrous layer(s) are called splits. Suede is made from this inner split layer, also known as the corium.

The name itself offers a clue to its history. “Suede” comes from the French phrase “gants de Suède,” meaning “gloves of Sweden.” This points to its early popularity in 18th-century Sweden for crafting exceptionally soft gloves, particularly favored by French nobility.

Key takeaway: Suede is real leather, but it originates from the inner, less dense, more fibrous part of the hide, which gives it its characteristic softness but also affects its durability.

How We Make Suede: From Hide to Softness

Creating that signature suede feel involves several key steps:

“

- Splitting: The thick animal hide is fed through a splitting machine, which horizontally slices it into layers. The top layer (grain) is separated, leaving the lower layer(s) – the splits. Suede utilizes one of these lower splits.

- Tanning: To preserve the split hide and make it stable, it undergoes tanning. This process prevents decomposition. Common methods include vegetable tanning (using plant extracts like mimosa bark) or chrome tanning.

- Napping: This is the magic step that creates the suede texture. The inner (flesh) side of the tanned split is carefully buffed, sanded, or abraded. This process raises the short, loose fibers, creating the soft, velvety nap that defines suede.

- Finishing: Finally, the suede is often dyed to achieve various colors and may receive other finishing treatments to enhance its appearance or feel.

Suede’s Signature Traits (Characteristics)

What makes suede, well, suede?

- Texture: Its most defining feature is the soft, velvety, fuzzy feel. The nap consists of relatively longer, looser fibers compared to nubuck, giving it a plush touch.

- Appearance: Suede has a distinct matte finish (no shine). Because it’s from the inner hide and heavily napped, it generally has a more uniform look and doesn’t show natural grain markings like scars or pores.

- Flexibility & Weight: Compared to full-grain leather or nubuck, suede is typically thinner, lighter, and more pliable. This flexibility allows it to drape beautifully, making it ideal for clothing.

- Breathability: The napped surface and the inherently looser fiber structure of the split layer make suede highly permeable. This allows air to pass through relatively easily.

- Water Resistance: This is suede’s Achilles’ heel. It has very low water resistance. The porous, absorbent nature means it stains easily and can be readily damaged by water.

The Pros and Cons of Suede

Let’s weigh the advantages and disadvantages:

- Pros: Exceptional softness and a luxurious feel are its biggest draws. It’s also lightweight, flexible, drapes well, and is generally more affordable than its top-grain counterpart, nubuck.

- Cons: Its main drawback is lower durability. Lacking the strong, dense grain layer, it’s more prone to tearing and wear. It stains very easily and is highly susceptible to water damage. Consequently, it requires more delicate care and maintenance, and the nap can attract and hold dirt.

Where Suede Shines: Common Applications

Suede is best suited for products where its softness, flexibility, and aesthetic appeal are prioritized, and where exposure to heavy wear, dirt, or moisture is limited.

Common uses include:

- Fashion footwear (dress shoes, loafers, boots – but avoid bad weather!)

- Apparel (jackets, vests, skirts)

- Accessories (gloves, handbags, wallets)

- Linings for other leather goods (providing a soft interior touch)

- Upholstery (offers a luxurious look but requires careful maintenance in high-traffic areas)

Expert Tip: Protecting Suede’s Delicate Surface

- Prevention is your best friend! Before you wear or use any new suede item, treat it thoroughly with a quality suede protector spray. This creates an invisible barrier to help repel water and prevent stains from setting in. Don’t forget to reapply this protection periodically, perhaps once a year or before seasons where you’ll use the item more often.

- Keep a suede brush handy. Regular gentle brushing (always in the same direction) helps remove surface dust and lifts the nap, keeping it looking fresh and feeling soft.

- Try your best to avoid wearing suede items in heavy rain or snow, as moisture is its primary enemy.

Nubuck Uncovered: The Durable Velvet

If suede is the soft, plush velvet, think of nubuck as its slightly tougher, more resilient cousin that still offers a luxurious, velvety touch.

What is Nubuck Leather? (Definition & Origin)

Nubuck is a type of top-grain leather recognized for its velvet-like surface, which often gets confused with suede.

The key difference lies in which side of the hide is used and how it’s treated. Nubuck is created by lightly sanding or buffing the outer (grain) side of the hide. This process creates a very short, fine nap.

The name “nubuck” is thought by some to be a combination of “new” and “buck,” possibly referencing its historical origins using buckskin (from deer or elk). While that might have been true initially, today, nubuck is most commonly produced from durable calfskin or cowhide.

Key takeaway: Nubuck starts with the stronger, outer layer of the hide (top-grain) but is finished to achieve a soft, suede-like feel, combining durability with a luxurious texture.

Crafting Nubuck: Sanding the Grain

Making nubuck involves refining the toughest part of the hide:

“

- Selection & Splitting: The process starts with selecting high-quality top-grain hides. While the final product utilizes the outer grain surface, the hide might still be split to achieve the desired thickness for the end product. The crucial part is that the outer grain surface is preserved for the next step.

- Tanning: Like all leather, the hides are tanned to stabilize the protein structure.

- Buffing/Sanding: This is the defining step for nubuck. The grain side (the outer surface) of the tanned leather is lightly sanded or buffed. This gentle abrasion removes the very top layer of the grain and raises the protein fibers slightly, creating a short, dense, fine nap. It’s a more delicate process than the napping of suede.

- Finishing: Because the sanding process alters the natural grain appearance, nubuck is almost always dyed to achieve uniform color and mask the sanding marks.

Nubuck’s Key Characteristics

What sets nubuck apart?

- Texture: It boasts a soft, velvety feel, much like suede, but the nap is noticeably shorter and finer. It often feels slightly more structured or even a bit more rugged compared to the plushness of suede.

- Appearance: Being made from the outer hide, nubuck often retains some subtle natural grain characteristics like pores or fine wrinkles, giving it more visual depth than suede. Rubbing the surface causes the nap to shift, slightly changing the color temporarily.

- Durability: This is a major advantage over suede. Because it’s derived from the strong, dense top-grain layer, nubuck is significantly more durable and resistant to wear and tear.

- Breathability: Nubuck is generally considered breathable. The sanding process can slightly open up the pores of the grain, allowing for better air and moisture vapor transmission compared to heavily coated leathers. It’s certainly more breathable than PU-coated split leather.

- Water Resistance: Nubuck handles moisture better than suede due to its tighter grain structure. However, it is not waterproof. Water droplets will typically darken the surface temporarily, but it often dries back to its original color (unlike suede, which may stain permanently). Using a protective spray is still highly recommended.

The Advantages & Disadvantages of Nubuck

Considering nubuck? Here’s the breakdown:

- Pros: Offers a unique combination of durability and softness. It has a luxurious appearance, is breathable, and requires relatively low maintenance compared to some other high-end leathers (mainly brushing and protection). It’s significantly stronger than suede.

- Cons: It’s typically more expensive than suede due to the higher quality raw material (top-grain) required. While durable against wear, its napped surface makes it more susceptible to scratches than smooth-finished leather (though minor scratches can sometimes blend into its rugged aesthetic). It can also be prone to staining, particularly from oily substances. Unlike traditional full-grain leather, nubuck does not develop a patina over time.

Nubuck in Action: Popular Uses

Nubuck excels in applications demanding a blend of resilience and a refined, soft touch.

You’ll often find it in:

- High-quality footwear (iconic work/hiking boots like Timberlands, casual shoes, premium sneakers, sandals)

- Accessories (durable bags, wallets, belts)

- Upholstery (offering a plush feel with better wear characteristics than suede)

- Apparel (jackets, gloves where durability is needed)

- Everyday items like phone covers

Expert Tip: Keeping Nubuck Looking Sharp

- Invest in a nubuck brush (often with softer bristles than a suede brush) or a nubuck eraser bar. Use these regularly to gently remove surface dirt and lift the fine nap, maintaining its velvety texture.

- Just like suede, apply a water and stain protector spray specifically formulated for nubuck before first use and reapply periodically. This is crucial for guarding against unexpected spills and moisture.

- If you do get a scratch, sometimes gentle brushing or rubbing with the eraser bar can help minimize its appearance, blending it into the nap.

Split Leather Demystified: The Versatile Workhorse

Now, let’s explore the foundation from which suede originates, and which can also be transformed into something entirely different: split leather.

Understanding Split Leather: The Lower Layers

Split leather refers to the fibrous lower layers of an animal hide, specifically the part called the corium, that remain after the top-grain layer (the outermost part with the natural skin surface) has been horizontally sliced off.

“

Think of a thick hide like a multi-layered cake. The top layer with the “icing” (the natural grain) is the top-grain leather. Everything underneath is considered split leather. This split section lacks the natural grain surface and doesn’t have the same dense, tightly interwoven fiber structure found in the top layer. Depending on the original hide’s thickness, it can sometimes be split again into multiple thinner layers.

Key takeaway: Split leather is real leather, derived from the animal hide, but it comes from the inner, structurally weaker part. Its final characteristics and usefulness depend almost entirely on how it’s processed and finished.

From Raw Split to Usable Leather: The Process

A raw split doesn’t look like much – it’s fibrous and rough, often resembling suede on both sides. To become a usable material for most products, it needs further processing:

- Splitting: As we’ve covered, the hide is split, separating the top grain from the lower layer(s) designated as splits.

- Tanning: The splits undergo tanning to preserve them.

- Finishing (The Crucial Step): This is where split leather gets its identity. Without finishing, its uses are limited. The two main paths are:

- Sueding: One side (usually the flesh side) is buffed or sanded to create a napped surface. This results in split suede, which we discussed earlier.

- Coating & Embossing: This is a completely different approach. A synthetic coating, typically polyurethane (PU) or sometimes vinyl, is applied to the surface of the split. Then, an artificial grain pattern is pressed onto this coating using heat and pressure. This creates what’s known as finished split leather, coated split leather, or sometimes bicast leather.

Core Characteristics of (Unfinished) Split Leather

Before finishing, split leather has these basic traits:

- Texture: Fibrous and somewhat rough, lacking the smooth grain of the top layer. If left unfinished, it feels suede-like on both surfaces.

- Durability: Significantly less durable and has lower tear resistance compared to top-grain leather. The fiber structure is looser and less organized.

- Flexibility: Can be quite flexible, especially when split into thinner layers.

- Cost: Generally the most affordable category of real leather due to being a byproduct of producing the more valuable top-grain.

Focus On: Finished Split Leather (PU Coated & Embossed)

This is where things get interesting, as manufacturers transform the humble split into something that looks like its higher-quality cousin.

Creating the Look: Coating & Embossing Explained

How is that smooth, grained appearance achieved on a fibrous split?

- Coating Application: A layer of liquid pigment or, more commonly, a polyurethane (PU) or vinyl solution/resin is applied evenly onto the surface of the tanned split leather. This can be done directly onto the split or by coating a special release paper and then transferring the PU film onto the leather using adhesives and heat.

- Embossing: To mimic the natural grain of top-grain leather, an artificial pattern is pressed into the coated surface. This is done using a heated metal plate or roller engraved with the desired texture (e.g., a typical cowhide grain, a pebble pattern, or even exotic patterns like crocodile or snake). The heat and pressure permanently imprint the pattern onto the PU coating.

- Result: The finished product is split leather with an artificial top layer that closely resembles the appearance of top-grain leather, especially when brand new. Bicast leather is a specific term often used for PU-coated split leather, particularly when it has a glossy finish.

Finished Split Traits (Appearance vs. Durability, Breathability, Water Resistance)

While it might look the part initially, finished split leather has very different properties:

- Appearance: Can look remarkably similar to top-grain leather when new. It often has a very uniform color and texture due to the artificial coating and embossing. It can sometimes have a noticeable shine or gloss.

- Durability: This is the major trade-off. While the PU coating offers some initial surface protection against scratches and spills, the underlying split leather remains structurally weaker than top grain. More importantly, the PU coating itself is prone to failure over time. With flexing, wear, exposure to sunlight, and body oils (especially on furniture or apparel), the coating can crack, peel, or become sticky. Finished split leather does not develop a rich patina like high-quality grain leather; instead, it tends to degrade and look worn out.

- Breathability: The polyurethane coating acts essentially as a layer of plastic on the surface. This significantly reduces or completely eliminates the natural breathability of the leather. Air and moisture vapor cannot pass through easily, which can lead to discomfort in clothing or footwear. It is far less breathable than nubuck or suede.

- Water Resistance: The PU coating provides a highly water-resistant surface. Liquids tend to bead up and roll off rather than soaking in, making it much more water-resistant than untreated split, suede, or even nubuck.

The creation of finished split leather highlights a fundamental manufacturing choice: prioritizing a specific aesthetic (imitating top-grain) and low cost over the inherent material properties found in higher-quality leathers. The process essentially builds an artificial surface onto a less robust base, rather than refining the natural strengths of the hide. This leads to a product that might look good initially but lacks the durability, breathability, and graceful aging potential of top-grain leather, failing in different ways (like peeling) due to its composite nature.

Weighing the Options: Split Leather Pros & Cons

So, when might split leather (in its various forms) be the right choice?

- Pros: The undeniable advantage is cost-effectiveness – it’s the most affordable type of real leather. It’s versatile, capable of being finished as soft suede or coated/embossed to look like grain leather. Finished splits offer good initial water resistance and are easy to wipe clean.

- Cons: The primary downsides are lower durability and tear strength compared to top-grain. Finished splits lack breathability due to the PU coating. The coating is also prone to cracking and peeling over time, especially in high-wear areas. Split leather doesn’t develop an attractive patina; it simply wears out. Finished splits can sometimes feel less luxurious or slightly “plastic-y”. Additionally, environmental concerns can arise from chrome tanning processes and the use of plastics in coatings.

Where You’ll Find Split Leather

Given its properties, split leather appears in specific market segments:

- Suede Splits: As covered previously – shoes, clothing, linings where softness is key.

- Finished/Coated Splits: Frequently used in budget-friendly furniture, often strategically placed on the sides and backs while more durable leather (or faux leather) is used on seating surfaces. Also found in inexpensive shoes, bags, belts, some automotive interiors (especially non-contact areas like door panels or headrests), and industrial items like work gloves or aprons where cost is a major factor.

Key Consideration: Decoding “Genuine Leather”

It’s worth repeating: if you see a product labeled “Genuine Leather,” proceed with awareness. This term is very often used in the industry to refer specifically to split leather, which may have been finished to look like top-grain.

While it is technically “real” leather (it came from an animal hide), it represents a lower tier of quality and durability compared to full-grain or top-grain leather. Don’t automatically equate “genuine” with “premium” or “best.”

The suitability of split leather hinges entirely on the specific application and priorities. For products where cost is the main driver, stress is low, or the unique texture of suede is desired, it can be a perfectly acceptable choice. However, for items demanding longevity, breathability, high wear resistance, and the ability to age gracefully, split leather (especially the finished/coated variety) is often a poor substitute for top-grain options like nubuck. The decision requires balancing the material’s inherent limitations against the product’s intended use, lifespan, and price point.

At a Glance: Suede vs. Nubuck vs. Finished Split Leather

Feeling overwhelmed by the details? Here’s a quick comparison table to help you see the key differences side-by-side:

Leather Comparison: Suede vs. Nubuck vs. Finished Split

| Feature | Suede | Nubuck | Finished Split (PU Coated) |

|---|---|---|---|

| Source Layer (Hide Part) | Inner Split (Corium) | Outer Layer (Top-Grain) | Inner Split (Corium) |

| Surface Processing | Buffed/Sanded (Flesh Side) | Buffed/Sanded (Grain Side) | Coated (PU) & Embossed |

| Feel/Texture | Soft, Plush, Fuzzy (Longer Nap) | Soft, Velvety (Shorter, Finer Nap) | Smooth, Potentially Plasticky/Stiff |

| Appearance | Matte, Uniform | Matte/Velvety, Subtle Natural Markings Possible | Uniform, Artificial Grain, Can be Glossy |

| Durability/Tear Resistance | Lower | Higher (Good) | Lower (Coating prone to peeling/cracking) |

| Breathability | Good | Good | Poor / None |

| Water Resistance | Very Low (Absorbent) | Moderate (Resistant but not waterproof) | High (Surface is water-resistant) |

| Typical Cost | Medium | High | Low |

| Common Uses | Shoes, Apparel, Linings, Delicate Goods | Footwear, Bags, Upholstery, Durable Goods | Budget Furniture (Sides/Back), Inexpensive Goods |

| Key Pro | Exceptional Softness | Durability + Softness | Low Cost + Grain Appearance (Initially) |

| Key Con | Low Durability, Stains Easily | More Expensive, Scratches Easier than Smooth | Low Durability, Poor Breathability, Peels/Cracks |

Export to Sheets

Data sourced from

This table provides a scannable overview, perfect for quickly comparing the critical factors when you’re choosing leather or evaluating a product. It distills the core differences into an easy-to-understand format.

Become a Leather Detective: Identifying Suede, Nubuck & Splits

Okay, you understand the theory. But how can you tell these leathers apart when you’re looking at a finished product? It takes a bit of practice, but here are the clues to look for:

“

Look & Feel: Key Differences

- Suede: Your eyes will see a distinctly fuzzy surface with a visible, longer nap. Run your hand over it – it should feel very soft and plush. The appearance is generally uniform, masking most natural hide markings. If you can see a cut edge, it might look quite fibrous.

- Nubuck: Look for a shorter, finer nap that feels like velvet. It’s soft, but often feels a bit firmer and denser than suede. Examine the surface closely – you might spot subtle hints of the natural grain, like tiny pores or fine wrinkles, which you won’t see on suede.

- Finished Split: This is often the trickiest. Look for a grain pattern that appears very uniform or repetitive – a sign of artificial embossing. The surface might have an unnatural shine or plasticky feel. It might feel stiffer than nubuck or suede. If you can see the back side, it will likely look fibrous or sueded, unlike top-grain leather which typically has a smoother (though still fibrous) flesh side after splitting.

Telltale Signs: Smell, Edges, Price

Beyond look and feel, other senses and context help:

- Smell: Get close and take a whiff. Suede and Nubuck should have that characteristic rich, natural, earthy leather smell. Finished splits with heavy PU coatings often betray themselves with a chemical or plastic-like odor.

- Edges: If you can see a raw cut edge (like on a strap or seam allowance):

- Top-grain (Nubuck base): You should see very dense fibers near the top surface, gradually becoming looser below.

- Split (Suede or Finished Split base): The fiber structure will look looser and more uniform throughout the thickness.

- Finished Split: You might even see a distinct line separating the PU coating from the fibrous split layer underneath.

- Price: Price is a strong indicator. Generally, Nubuck (as top-grain) > Suede > Finished Split. If a product looks like high-quality grain leather but the price seems surprisingly low, it’s often finished split leather.

- Water Test (Use With Caution!): On a hidden, inconspicuous spot, place a single drop of water:

- Suede: Water will likely soak in quickly and darken the area.

- Nubuck: Water may bead initially but will likely darken the spot as it slowly absorbs.

- Finished Split (PU Coated): Water should distinctly bead up and roll off the surface without absorbing. (Always test this carefully, as some leathers may have factory water-repellent treatments applied).

Identifying leather accurately often requires combining these observations. You can’t always rely on just one factor. Finished splits are specifically designed to look like top-grain leather from a distance. Therefore, relying solely on the surface appearance can be misleading. Engaging multiple senses – feeling for that plastic touch, smelling for chemicals, examining the edges, and considering the price point – provides a much more reliable assessment than just looking at the potentially deceptive surface.

Leather Care 101: Keeping Suede, Nubuck & Finished Splits Pristine

You’ve chosen your leather – now how do you keep it looking its best? Critically, care methods differ significantly between these types. Using the wrong product can do more harm than good!

Suede Care Guide

Suede needs gentle handling:

- Protect: Regularly apply a suede protector spray to repel water and stains.

- Clean: Use a dedicated suede brush to remove dry dirt and revive the nap. For tougher spots, try a suede eraser. If you spill liquid, blot immediately with a clean, dry cloth – don’t rub! Specialized suede cleaners can be used for persistent stains.

- Water: Avoid getting suede wet if possible. If it does get wet, let it air dry naturally, away from direct heat sources (like radiators or hairdryers). Once completely dry, use the suede brush to restore the texture.

- Storage: Store suede items in a breathable fabric bag (like cotton) to prevent dust buildup, away from direct sunlight which can cause fading.

Nubuck Maintenance Tips

Nubuck is tougher, but still needs care:

- Protect: Apply a protector spray suitable for nubuck to guard against water and stains.

- Clean: Use a nubuck brush (often slightly softer than suede brushes) or a nubuck eraser bar for routine cleaning and nap restoration. Cleaning blocks or specific nubuck foam cleaners can tackle marks and stains.

- Conditioning: Standard nubuck generally does not require conditioning like smooth leather. Applying oils or creams can flatten the nap and darken the color permanently. Exceptions exist for specific types like oily nubuck or certain roughout leathers, which may require specific oils or waxes – always follow manufacturer recommendations.

- Water: While more resistant than suede, it’s still best to protect nubuck from heavy moisture. If it gets wet, allow it to air dry naturally.

Caring for PU-Coated Split Leather (Do’s & Don’ts)

This requires a completely different approach, focused on maintaining the coating:

- DO: Wipe the surface regularly with a dry or slightly damp, soft, lint-free cloth to remove dust and light grime.

- DO: Use a dedicated PU Protector product every 3-6 months, especially on areas that have frequent skin or hair contact (like armrests or headrests on furniture). Body oils and sweat can degrade the PU coating over time. These protectors clean gently and help maintain the coating’s integrity and appearance.

- DO: For more thorough cleaning, a solution of warm water and a few drops of mild dish soap applied with a microfiber cloth usually works well. Wipe evenly and then buff dry with a clean cloth. Some pH-neutral multi-surface cleaners might also be suitable, but always test first.

- DO: Always test any cleaning product on a hidden, inconspicuous area first to ensure it doesn’t cause discoloration or damage.

- DON’T: Never use traditional leather conditioners, waxes, oils, or creams! These products are designed for porous natural leather and can penetrate or react negatively with the polyurethane coating, often making it sticky, dull, or causing it to break down prematurely.

- DON’T: Avoid abrasive cleaners, solvents, furniture polish, or harsh chemicals like bleach or highly acidic/alkaline cleaners, as these can strip or damage the PU coating.

- DON’T: Avoid excessive heat. While gentle heat from a hairdryer might sometimes minimize very light scratches (test carefully!), too much heat can permanently damage the coating. Keep PU-coated items away from direct heat sources.

- BE AWARE: Once the PU coating starts to significantly crack or peel, repair is very difficult or impossible. Prevention through regular, correct cleaning and protection is the best strategy. For furniture, consider using throws or blankets on high-contact areas to minimize direct exposure to body oils.

The stark difference in care requirements underscores why correct leather identification is paramount. Applying a standard leather care routine, rich in oils and waxes , to a PU-coated item will likely accelerate its demise rather than preserve it. Conversely, using only surface cleaners on porous suede or nubuck won’t provide the necessary protection against stains and moisture. Care must match the material type.

Expert Tip: The Power of Prevention

Across all these leather types, one piece of advice stands out: prevention is far easier than cure.

- For Suede and Nubuck, that first application of a high-quality protector spray before you ever use the item is the single most effective action you can take. It provides an immediate shield against the inevitable spills and splashes of daily life.

- For PU-coated Split Leather, the key is regular, gentle cleaning combined with periodic use of a PU-specific protector. This routine combats the gradual breakdown caused by environmental factors and contact with skin oils, significantly extending the life of the coating.

Choosing Wisely: How Understanding Leather Details Elevates Your Product

Why does all this technical detail matter? Because the choice between suede, nubuck, and split leather has profound implications that go far beyond just how a product looks.

This decision impacts:

- Manufacturability: How easily can the leather be cut, stitched, and shaped? Does it require special reinforcement? Suede and thinner splits might be more flexible but less structurally sound.

- Product Lifespan: How will the item wear over time? Will it develop character (patina) or simply degrade (peel/crack)? Top-grain options generally offer far greater longevity.

- User Comfort: Is breathability important? For footwear or clothing worn close to the skin, the non-breathable nature of PU-coated split can be a significant drawback compared to nubuck or suede.

- Brand Perception: The materials you choose reflect on your brand’s commitment to quality, durability, and value.

Matching Material to Application is Key:

- Need rugged durability combined with a soft, premium feel for items like quality boots or frequently used bags? Nubuck is often the superior choice.

- Is the priority ultimate softness, light weight, and excellent drape for items like apparel linings or delicate accessories where wear is minimal? Suede could be the perfect fit.

- Is cost the absolute primary driver for a budget-conscious product, and a smooth (albeit artificial) grain appearance is desired? Finished Split might be considered, but only with a full understanding of its significant limitations in durability, breathability, and aging.

For designers and manufacturers, this knowledge empowers you during sourcing. You can ask suppliers the right questions, specify your requirements accurately, and ensure you’re receiving (and paying for) the material quality you expect.

For everyone, this understanding builds trust. As a manufacturer, demonstrating expertise inspires confidence. As a consumer, being informed allows you to make smarter purchasing decisions and appreciate the true value of well-crafted leather goods.

The Takeaway: Grasping the nuances between suede, nubuck, and the various forms of split leather isn’t just about knowing definitions. It’s fundamental knowledge for anyone involved in creating, selling, or buying leather goods. It enables the selection of materials that are truly fit-for-purpose, leading to higher quality products that meet expectations and deliver genuine, lasting value.

Now that you’re equipped with a deeper understanding of these versatile leather types, perhaps you’re ready to explore materials for your next project or find the perfect leather product.

Explore our curated collection of [mention company’s relevant product category, e.g., premium nubuck accessories or quality suede materials] or feel free to contact our leather experts today. We’re here to help you navigate the world of leather and find the perfect solution for your needs! Sources used in the report